The simDrive AC Servo Driver is a link between a computer system and the mechanical components of the machine. It allows the device to perform a set of programmed activities. The simDrive AC supervises the machine’s operations and communicates with the user through a purposefully designed interface.

Servo drivers are used in order to retrofit various types of equipment, namely:

- horizontal mills,

- vertical mills,

- lathes,

- grinders,

- automatic welding machines,

- turning centers,

- EDM,

- inspection equipment.

The Application of the SimDrive™AC Servo Driver

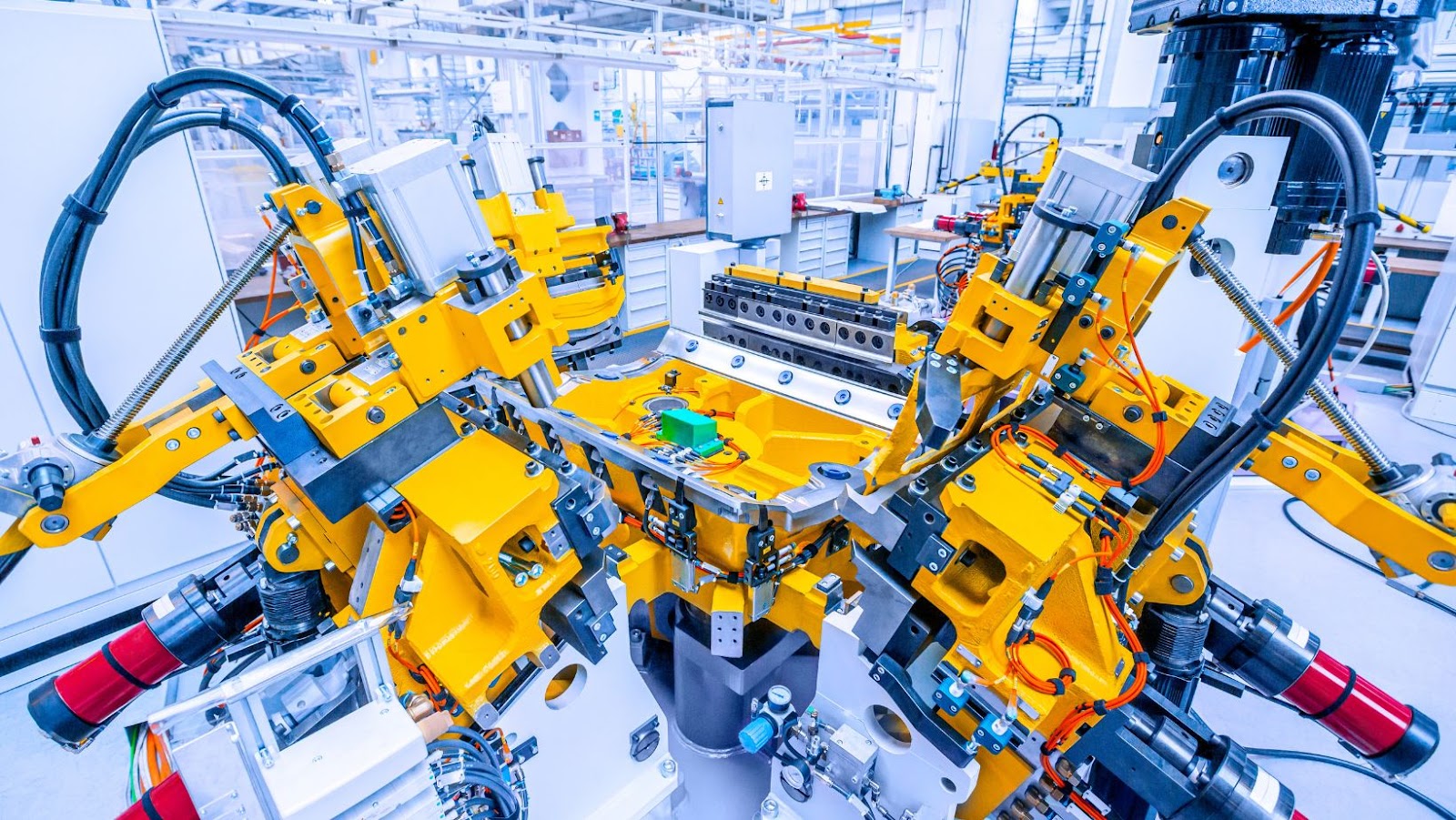

The simDrive Servo Drivers are particularly compact and strong, and as such, they can play many different roles. They are commonly used in automobiles, manufacturing, electrically operated machinery, remote-controlled devices, and robotics, to name a few.

Automobiles

Servo drivers are used to control the speed of modern-day cars. They are also part of the commercial planes’ design – they push and pull everything within the construction of the aircraft.

Manufacturing

Servo drivers are part of the manufacturing process in situations, where position control and rotation at precise angles and distances are essential. They are commonly used by such industries as food services, pharmaceutics, and in-line manufacturing.

Electrically Operated Machinery

Various types of electrically operated machinery also use servo motors. These are mostly elevators, rudders, and operating grippers.

Remote-Controlled Devices

Servo drivers are used in order to achieve movement in remote-controlled devices, mostly toys, such as cars, planes, and helicopters. Moreover, they are implemented to position control surfaces in radio-controlled airplanes.

Robotics

Robotics is the most important sector in which servo drives are implemented. Due to such characteristics of servo drives as small size, accuracy, programmability, big strength, and almost flawless repeatability of motion, they are commonly used in robotics, especially in:

- Robot welding, where they are mounted in every joint of a robotic welding arm in order to actuate the movement and add dexterity,

- Robotic vehicles, where they are implemented in the steering systems of the highly specialized vehicles used to disarm and dispose of the explosive materials.

It is worth mentioning that servo drivers are also commonly applied in everyday items, such as DVD and Blu-ray players, where they are used to extract and retract disc trays.

How to Set Up the SimDrive™AC Servo Driver?

SimDrive AC Servo Driver is equipped with a diagnostic utility software – csServoManager – which is an extremely convenient software installer. It allows for an easy installation process that runs almost entirely automatically. The users do not have to struggle through all the parameters and settings to successfully operate the drive. They just need to follow some very basic instructions.

The csServoManager offers ready-to-load profile templates, which are available for 400W and 750W motors. They contain all the electric parameters of a motor, an encoder, and hall sensors. By using the pre-prepared settings, the user can eliminate any doubts, avoid uncertainties, and save a lot of time. After loading the settings from the configuration profile template and setting the simDrive AC by default, as required by the driver’s manual, the only necessary configuration remaining is PID loop tuning.

Advantages of the SimDrive™AC Servo Driver

CS-Lab offers various models of the simDrive AC Servo Drivers. They all have a relatively narrow range of applications, which allows for a simple and easy configuration. Moreover, they can be installed and used without the need to delve deep into a large number of parameters. Thanks to these features, the simDrive AC Servo Drivers are exceptionally user-friendly. Among the advantages of the servo drivers offered in the CS-Lab Shop, the one’s deserving special mention are compact architecture, high power density, rapid response, overheat capability protection, and various frame installations.